Gen 2 turbochargersNew High Efficiency Gen2

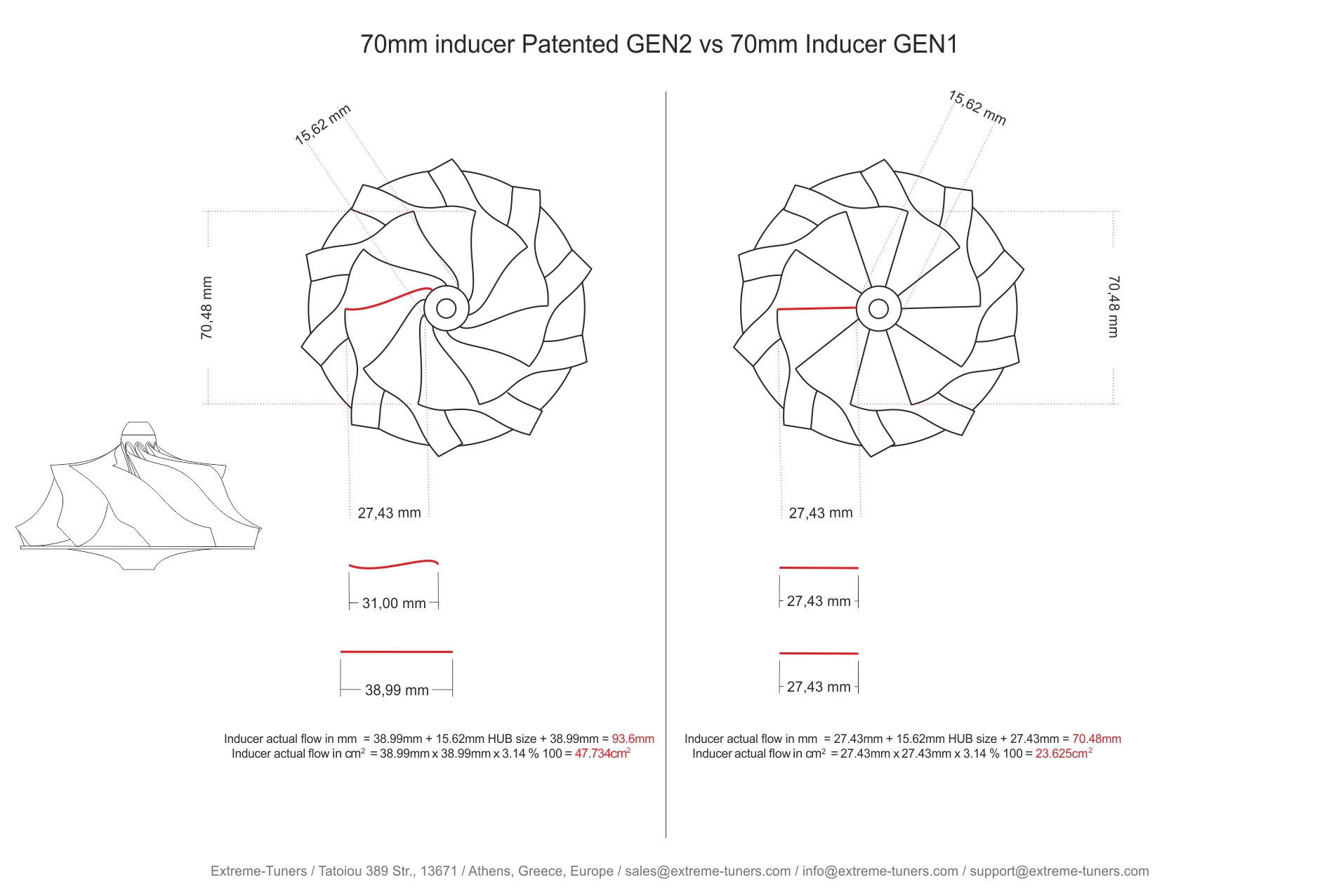

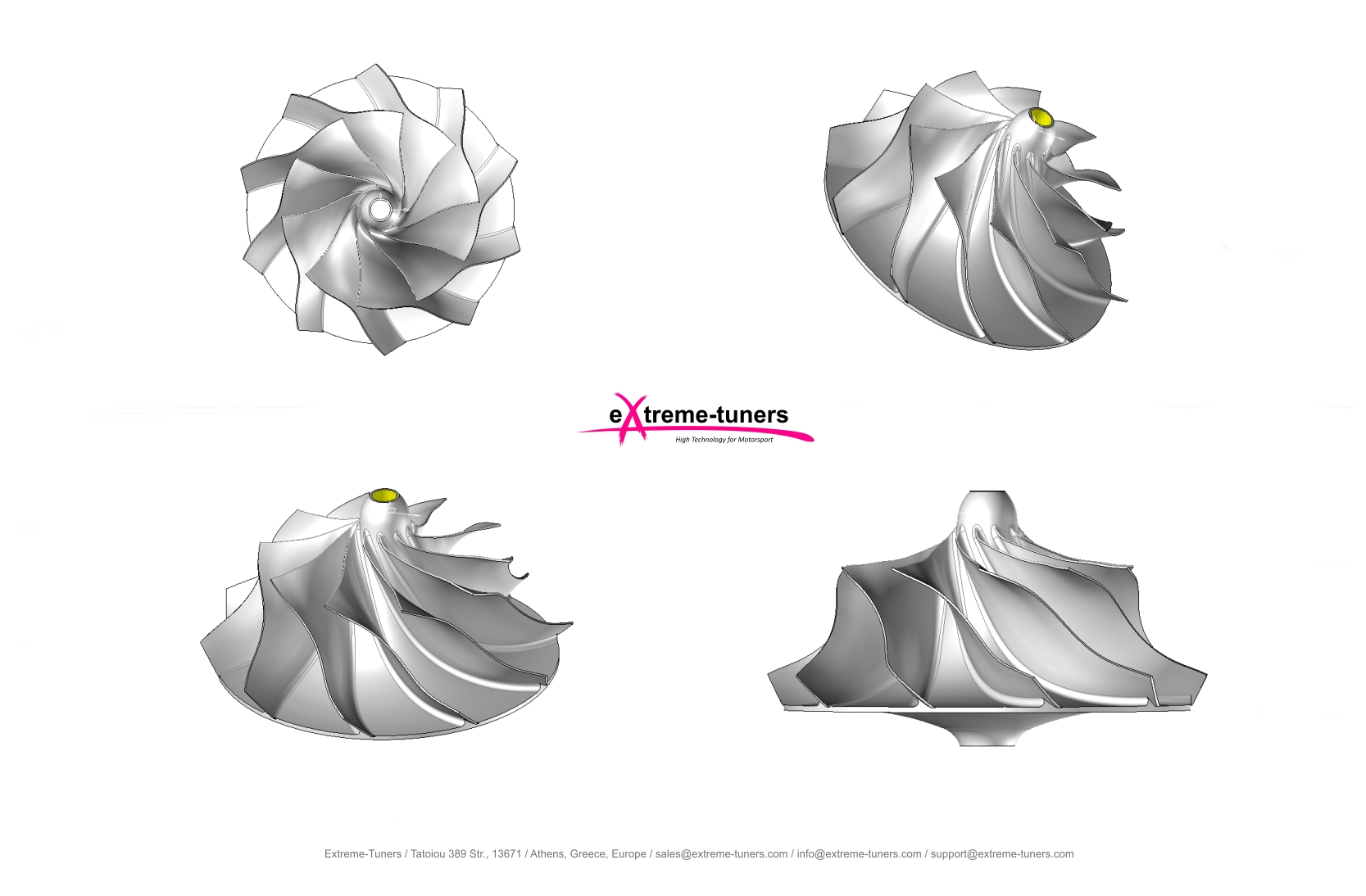

A next generation of compressor wheel, for a turbocharger revolutionary improved aerodynamically, improved geometry that provides 35-80% more performance as compared with a comparably sized conventional compressor wheel by having the radially inward portion of the primary blades sweep upwardly into the upper region of the hub portion. The through bore and integral nut of compressor wheels is eliminated and replaced with a blade extension that has an angled upper edge which extends downwardly and radially outwardly from the hub portion, that’s the Curve towards the root design, and second base design is the two-way curve in the blade from top view. One way starting from hub with one rotation and at the opposite (end) of the same blade the second curve rotation is different direction.

These 2 points (Curve towards the root-hub) and Curve of blade two way effectively increasing the size of the blade, the amount of air movement and the amount of power generated, without increase the size and mas weight of the compressor wheel.

The compressor wheel blades are in one line fitted to hub and not as the normal old style compressor wheels fitted in two rows (primary and secondary), the benefit of this is that the moving masses of air in the same rotation speed of the compression wheel can be 43%-68% more than any other two row old design, making the wheel taller also allow grab more air and to flow better at higher boost levels as well.

The wheels may vary from size and application, 9/10/11/12/13/16 number of blades.

Same size wheel but different design can built for low spool applications, for throttle response, for high p2/p1, for mid boost and mass volume, or combining many.

The compressor wheel material also vary depends the size and the type of racing.

Compressor wheel materials are:

- Billet 5 axis flank milled Aluminum T6 series

- Billet 5 axis point milled Aluminum T6 series

- Billet 5 axis point milled Titanium

- Billet 5 axis point milled Magnesium

- Billet 5 axis point milled Aerospace Alloy 970Mpa Yeld strength

- Carbon composite Fiber

- Carbon Kevlar