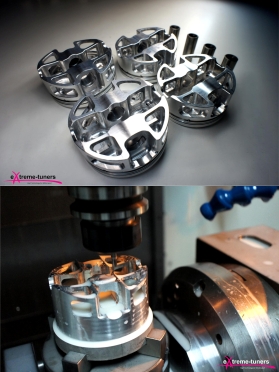

ENGINE COMPONENTSPistons

Our Engineering department started off analyzing the competition, gathering industry data and deciding to make the highest level of pistons.

Just a quick terminoligy billet vs cast

Diferences billet vs cast

All materials start out at some point as a cast chunk. There is a big difference though in a cast part and a billet chunk of aluminum. The actual naming convention is that a square or rectangular chunk is called a billet, and a round chunk is called a round, but the name billet in aftermarket circles has come to mean “strong because it is made from a block of metal”.

A cast part is made from material being forced or poured into a mold. The part will have thicker and thinner areas, and takes shape from this molten state. Therefore the material must have good castability. One of the main properties of a material that has good castability is that it does not form internal voids on cooling. As a material cools, it shrinks. If there are thick and thin areas, the thick areas will cool slower than the thin ones, and the thick areas can form voids, and the part can warp out of shape or crack, or worse, form internal stresses that come out when the part is used, then crack later. These materials are typically more brittle. A cast piston is “weaker” because it is made from cast or nodular cast aluminum, not really because it is cast. It is cast because the material is very castable, but is impossible to forge. A billet may start out cast, but the shape is very very even and symmetrical, so the above concerns do not come into play as in a cast part of some odd shape.

A forged part is made from a chunk of metal. It is then usually heated, and it is pounded into shape in a forging die. The extra metal oozes out from between the forging dies and must be ground off. This is why there is a wide parting line on forged parts.

Now here is the key with billet parts... billet parts have the capability of being of higher strength than a forged part. It depends on what kind of alloy the part is made from. A billet part is cut from a solid chunk of aluminum, so the material does NOT have to be forgeable. You can make parts out of superior strength materials to forging, because you do not have to pick a material that is forgable. Again, this does not stop the designers from picking a weak cheap material, knowing gearheads will buy the parts because the box says “billet”. The biggest drawback to a billet part is they must be fully machined.

When shopping for parts in the future, remember what the terms "billet" and "forged" really mean. When shopping for the best of any product, the better you understand the terminoligy and the science behind the product, the better your decision making will be. When someone advertises a product as being "billet aluminum", or "forged" you should be asking "what kind of alloy?" or "what grade of aluminum?" or "what are the material properties?"

As for us, we built only billet pistons from the highest alloy properties on the market.

Utilizing State-Of-The-Art CNC machines for manufacturing along with purpose-designed billets, we are able to maintain exacting specifications on each and every piston and hold tolerances to millionths of an inch. Also available from us industry-leading processes, like 5axis Digital 5 dimentional piston crown machining process and Finite Element Analysis (FEA). FEA is a computer process whereby stress and fatigue are tested on a computer model before it goes into production. The ISO 9001:2008 quality standard which confirms that we provides customers the highest standards in quality control. In addition, we also have State-Of-The-Art inspection equipment and testing equipment which enables us to constantly bring you, the customer, the very latest in piston design configurations.

We have a large variety of pistons available for all famous brands.For brands not listed, we always have the option to produce any high-tech custom designed pistons, according to customers’ demand.

*GEN1 pistons (eventually we will stop production on those and move to ultimate GEN2)

Billet pistons 2D 4032 material (no pocket design)

Billet pistons 2D 4032 material (pocket design or assymetrical)

Billet pistons 3D 4032 material (full pocket design or assymetrical)

Billet pistons 2D 2618 material (no pocket design)

Billet pistons 2D 2618 material (pocket design or assymetrical)

Billet pistons 3D 2618 material (full pocket design or assymetrical)

Methanol / Nitromethane / Drag spec Billet full pocket design + assymetrical bridged

Skeleton piston / Drag spec Billet full pocket design + assymetrical bridged

*GEN2 pistons ! The ultimate billet pistons, 5 axis CNC and EDM built. F1 class technology.

* We can upgrade piston material with our Aerospace custom alloy 970Mpa yield strength in additional cost.

Gen2 pistons is our chalenge with perfection. X design.